Nowadays, flexible electronics has become the subject of active research. Although, flexible magnetic memory devices have attracted a lot of attention. Additionally, it becomes a basic component for data storage and processing in wearable electronics and biomedical devices. There is various research going on to develop different types of memory storage and materials. Similarly, scientists from National University of Singapore (NUS) have successfully implanted powerful magnetic memory chip on a flexible plastic material.

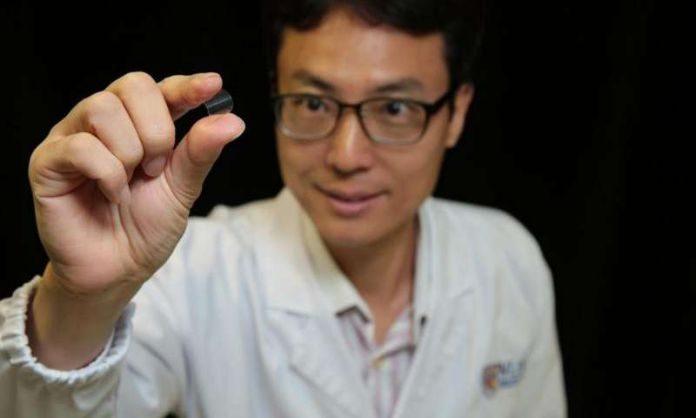

This flexible device allows researchers to take one step forward to build flexible and wearable electronics. It is similar to a small transparent film having small cuts on it and can be bent easily into a tube. Still, this smart plastic memory device has excellent performance in terms of data storage and processing capabilities.

Working of This New Flexible Magnetic Plastic Memory Device

This new plastic memory device performs on magnetoresistive random access memory (MRAM). This MRAM uses magnesium oxide (MgO)-based magnetic tunnel junction (MTJ) to store data. MRAM performs on typical RAM computer chips in various features. The features like retaining data after the power supply cut off, high power speed and less consumption of electricity.

Scientists primarily evolved the MgO-based MTJ on a silicon surface and then cut basic silicon. By using transfer printing method, researchers inserted the magnetic memory chip on a flexible plastic surface. Tese plastic surface made up of polyethylene terephthalate. This implantation process is done during controlling the amount of strain caused by placing the memory chip on the plastic surface.

This research shows that the device covers magnetoresistance could reach at above 300 per cent. Researchers also improved slope of switching.

Assoc Prof Yang said, “Flexible electronics will become the norm in the near future, and all new electronic components should be compatible with flexible electronics. We are the first team to fabricate magnetic memory on a flexible surface, and this significant milestone gives us the impetus to further enhance the performance of flexible memory devices and contribute towards the flexible electronics revolution.”

In conclusion, this novel plastic memory device with various features is able to transfer data faster. This will be used in automotive, healthcare electronics, industrial motor control and robotics, industrial power and energy management, as well as military and avionics systems.